CAD-CAM & 3Shape

CAD-CAM & 3Shape

CAD-CAM TOOTH REPLACEMENT FROM THE COMPUTER

CAD-CAM has become an indispensable part of dental technology. All-ceramic dentures can be produced quickly and inexpensively in high quality. The burden on patients and the manual workload for dentists and dental technicians are significantly reduced with the digital workflow. However, computer-aided production is not always suitable. Conventional manual labor is also indispensable for a number of activities.

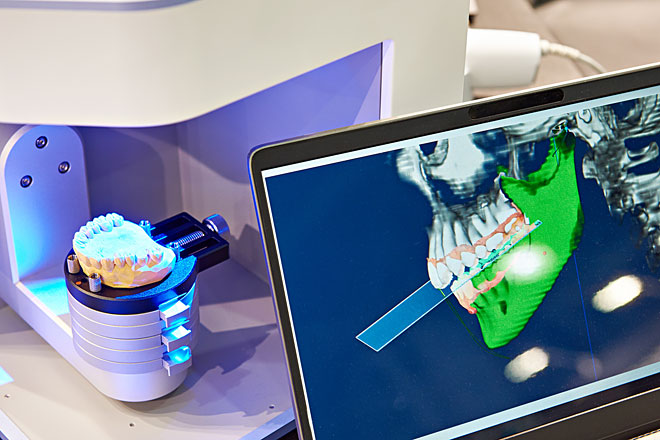

With CAD-CAM technology (CAD = Computer Aides Design, CAM = Computer Aides Manufacturing), high-quality dentures such as bridges, crowns, inlays, implants and prostheses are created from digital 3D images in a very short time. Depending on the procedure – labside or chairside – the exact digital measurement of the tooth situation can save the unpleasant bite into the impression material and also save a lot of time.

WHAT DOES CAD-CAM MANUFACTURING MEAN?

A three-dimensional digital image provides the dentist and the dental technician with a complete, detailed representation of the individual oral situation in a CAD program. Based on these images, the planned denture is digitally built with the highest possible accuracy of fit. A computer-controlled station (CAM) uses milling and grinding to create the desired dentures from a blank.

ADVANTAGES OF CAD-CAM

– Less work for the dentist and dental technician.

– Inexpensive dentures through automatic production.

– You save the unpleasant bite impression (in the chairside procedure).

– Highly compatible, tooth-colored inlays, implants, crowns and bridges made of zirconium.

– Optimal adaptation of the chewing surfaces through digital chewing and speaking simulation.

– The function of the denture in the dentition can be simulated.

– The data record can be supplemented with bone structures from a 3D X-ray machine.

– Zirconium dentures are also suitable for patients with a metal allergy.

– The data set created can be used as often as required.

WHAT DOES LABSIDE MEAN?

The labside procedure combines digital technology with the competence of the dental technician. In the practice, the dentist takes a conventional bite impression of the patient. The impression of the dentition is sent to the dental laboratory, which uses it to create the master model. In the labside process, the master model is digitized with the CAD-CAM software. The three-dimensional image of the affected prepared teeth serves as a template for the construction of the new denture. With the program of the CAD-CAM software, inaccuracies and occlusion problems can be corrected and chewing movements of the jaw can be simulated. The computer-controlled milling machine then takes over the production of the dentures. The dental technician finishes the chewing surfaces manually and refines the dentures in detail with colored ceramics and polish.

WHAT DOES CHAIRSIDE MEAN?

In the chairside procedure, all work steps of the CAD-CAM technology are carried out in practice. With a special intraoral scanner, the dentist takes a precise digital impression of the prepared tooth. Inaccuracies and occlusion problems can be corrected in the CAD software, and chewing and speaking movements of the jaw can also be simulated with the software. Then the computer-controlled milling machine takes over the production of the dentures fully automatically from a whole piece of material. This procedure is mostly used for single tooth restorations. Often the finished tooth can be fitted to the patient in a single appointment. This eliminates the need to make and wear a temporary solution.

3SHAPE DENTAL SYSTEM

Together with dentistry experts from all over the world, 3Shape develops innovative products to guarantee patients the best possible dental care. The portfolio of 3D scanners and CAD / CAM software solutions includes the multi-award-winning 3Shape TRIOS intraoral scanner and market-leading scan and design systems for dental laboratories.

The digital impressions, which can be created in true-to-life colors, the color determination and the built-in intraoral camera for taking HD photos enable dentists to better evaluate the treatment and to shorten the treatment time.

The seamless forwarding to implant manufacturers, providers of orthodontic treatment solutions and patient management systems simplifies the process.

In the 3Shape system, complete impressions, stumps, implants or wax-ups can be automatically scanned in order to then design the desired restoration from the scans.